Sometimes people make mistakes when soldering (or perhaps you are fixing something someone else put together). You may have to DE-solder a connection or two. There are several methods used for desoldering, but they employ the basic following steps. First, you heat up the iron as if you were soldering, and test to make sure it will melt solder. Then you touch the flat surface of your iron, to the largest surface you are trying to de-solder. Wait until you see the solder flow (it will change in appearance, and you'll see that shiny liquid look). Now gently pull the component loose from the connector. I say gently - some components may require additional effort, but if you have to pull out a crow bar - you are doing something wrong.

If you are dealing with a capacitor (Electrolytics can be pesky ), resistor, or diode, heat and pull one leg at a time. It may help to "rock" the component back and forth as you alternately heat it's connectin point. If you are dealing with parts on a printed circuit board, the pads can be accidentally lifted off either by applying too much heat, or by applying too much force when the component isn't ready to come off yet.

Take great care when removing parts off a printed circuit board. If you are removing a transistor - again rock the part from side to side, alternating heat from one leg to another. If you are removing an integrated circuit of any kind - you need to remove the entire IC all in one movement, or you will physically damage it.

As an aid to removal of components - there are certain supplies and tools that can make the job easier. As an aid to removal of components - there are certain supplies and tools that can make the job easier.

First is a vacuum pump. These come in both manual, and electric types. A manual pump may be just the trick for removing one part, but will give you a hand cramp over time. It is simple to use. Simply ready the pump, heat the connector, then suck. The big advantage to the hand desoldering pump is price. You only have to buy it once, and it isn't very expensive. The disadvantage is that it gets clogged up with solder, and needs to be taken apart and cleaned occasionally, and that if you use it several times a day, your hand can begin to hurt. Electric vacuum pumps take away the problem of the hand cramp - but they still get clogged and need occasional cleaning.

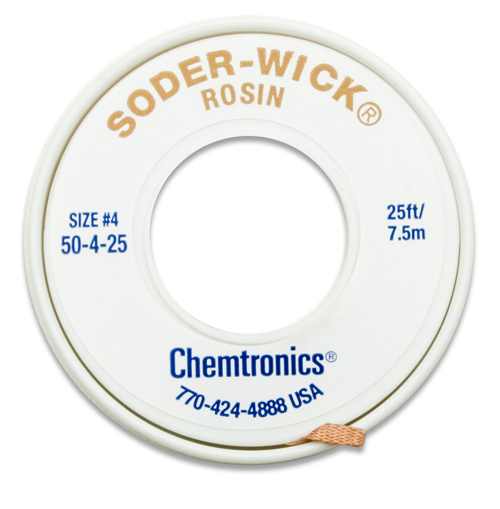

Another tool that is useful for removal of solder is "solder wick". Essentially a braid of very thin wire, solder wick does a fine job of removing solder, and you can use it quite effectively to remove Integrate Circuits and transistors, as well as other components. The big drawback of solder wick is that it is one time use, and expensive. It comes on a spool, and you touch it against the connection you are trying to remove the solder from. You put it BETWEEN the soldered connector, and your soldering iron. When it heats up, it will soak up the solder - then you remove it, cut off what you used, and throw it away. Note it is made of expensive COPPER, and as such - is expensive! If you find a way to reclaim it inexpensivly and easily - please - write me! As a side note - I have used the braid from a spent coaxial cable for the same purpose in the past with great success. Another tool that is useful for removal of solder is "solder wick". Essentially a braid of very thin wire, solder wick does a fine job of removing solder, and you can use it quite effectively to remove Integrate Circuits and transistors, as well as other components. The big drawback of solder wick is that it is one time use, and expensive. It comes on a spool, and you touch it against the connection you are trying to remove the solder from. You put it BETWEEN the soldered connector, and your soldering iron. When it heats up, it will soak up the solder - then you remove it, cut off what you used, and throw it away. Note it is made of expensive COPPER, and as such - is expensive! If you find a way to reclaim it inexpensivly and easily - please - write me! As a side note - I have used the braid from a spent coaxial cable for the same purpose in the past with great success.

|