There are several kinds of solder, and not all of them are suitable for electronics work. Solders can be categorized by Materials, hardness, melting point, and type of core.

Materials

There are many materials that solder CAN be made from. Typically in electronics, a 60/40 mixture of tin and lead were used. Similarly a 63/37 mixture of lead and tin can be found. These are both moderate temperature solders that are easily used for electrical work. There are many materials that solder CAN be made from. Typically in electronics, a 60/40 mixture of tin and lead were used. Similarly a 63/37 mixture of lead and tin can be found. These are both moderate temperature solders that are easily used for electrical work.

There is a problem though. Lead is considered by experts to be a poison. I say it is "considered" a poison because while some "far better qualified than I" organizations which claim that as little as 10 micrograms of lead per deciliter of blood (μg/dL) is harmful (that's 1/100,000 of a gram per liter of blood), I've been handling lead in the form of solder for over 35 years, and show no signs or symptoms of lead poisoning. I think it might be poisonous if you eat it, although I've known kids that grew up quite healthy, who in their childhood used to peal lead based paint chips off the school room walls and eat it!

Well, I say that - but the symptoms are typically balding, headaches, abdominal pain, memory loss, kidney failure, and weakness, pain, or tingling in the extremities. It seems to me that with folks my age - most of those "symptoms" apply - even if we haven't played with solder. That being said - I only have abdominal pain when I eat jalepenos, show no sign of balding, and the only weakness, pain, and headaches I have can be atributed to a hard, stressful day at work.

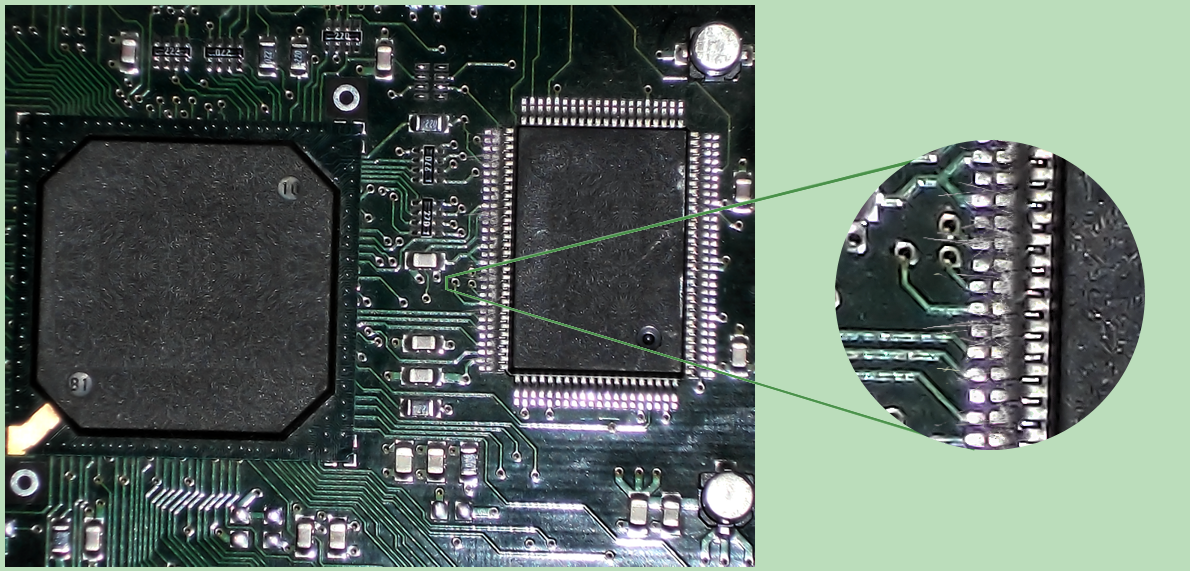

Nevertheless, because of these warnings, lead is being reduced in landfills, by reducing the amount used in electronics production. In short - newer "lead free" solders are being used nowdays which are harder to solder (requires more heat), and after some time developes "tin whiskers" on them which can affect radio frequency equipment and high speed computer systems adversely. So much for progress. As an interesting side note- lead based solder has also been banned from use in plumbing. I find this especially interesting, as the word plumbing comes from the Latin root word Plumbus, which is the Latin word for lead. Funny how plumbers don't use plumbus anymore because of fear based government regulation. In short - if you are afraid of touching lead - wear gloves. Nevertheless, because of these warnings, lead is being reduced in landfills, by reducing the amount used in electronics production. In short - newer "lead free" solders are being used nowdays which are harder to solder (requires more heat), and after some time developes "tin whiskers" on them which can affect radio frequency equipment and high speed computer systems adversely. So much for progress. As an interesting side note- lead based solder has also been banned from use in plumbing. I find this especially interesting, as the word plumbing comes from the Latin root word Plumbus, which is the Latin word for lead. Funny how plumbers don't use plumbus anymore because of fear based government regulation. In short - if you are afraid of touching lead - wear gloves.

**Politically speaking - (stepping up onto my political podium) Tin whiskers is a VERY REAL problem that proponents of RoHS compliance are afraid to discuss, because it is far more dangerous than the lead poisoning they are fighting to stop. Tin whiskers are the natural chemical result of crystalline growth of the metal tin in the absense of lead. "RoHS compliance" - an international push to get rid of lead in landfills has caused electronics manufacturers to curb the use of lead, which is now creating more of a tin whisker problem in the electronics world. It has been shown that Tin Whiskers was the cause of at least one $250,000,000 satellite to go bad in space (Galaxy 4) and are expected to cause even more problems. Tin whiskers can take place in the confines of space, and unseen inside the packaging of transistors and integrated circuits. Tin whiskers, due to RoHS compliance, are now able to be found in any kind of electronics anywhere in the world, including Military Weapons and Nuclear Plants, and the brakes on the car you drive use electronics. So when the Nuclear plant 20 miles from you, goes Fukishima, or the nuclear missile accidentally launches and lands and blows up in your home town and kills millions of people - you can blame it on the "save mother earth" people who are afraid of putting the lead back where it came from - the earth - because it might leach out and get in your water, and make me grow bald by the time I'm 60 years old.(steps down)

Whenever we change the metals that solder is made of, we also change its other physical properties, such as melting point and hardness. Some types of solder are specifically chosen for these properties. For instance - you want a hard lead when working with pipes, but a low melting point when working with sensitive microprocessor chips.

Solder comes in two types of core - Solid and Hollow. The solid is what it says it is - solid solder. The Hollow core type is a bit misleading. It isn't truly hollow. It is filled. Hollow core solder has some kind of FLUX in the middle of it. The purpose of the flux is to make it flow better. There are typically two types of flux found in the "hollow" core of solder. The first type is ACID core, which is absolutely NEVER to be used in any electrical work. It may be fine for plumbing or stained glass work - but acid core solder will eat circuit boards, destroy components, etc. Instead - ROSIN core solder is used in electrical work.

So, after all this babbling - what are you looking for in a solder? Well, if you plan on eating it - find something lead free. Otherwise, if you are going to do electrical work, you want Rosin Core 60% tin, 40% lead (60/40) or 63/37 will work just fine for MOST soldering you will be doing.

|