Home Made Resistors The Resistor is by far one of the most common components used in electronics, yet they are taken for granted. We can often run down to the corner electronics shop and by them, or scrounge them from a thrown out television set. But at one time this wasn't true (and in some countries it still isn't). Until resistors were made comercially available, they had to be fabricated by the person wanting to use or experiment with them. This has become a bit of a lost art, but I'd like to bring it back - simply for the knowledge to be passed down, and for others to perhaps build upon. (Note - if you find any good ideas I do not list, please pass them along to me so I can help share them with the global conscience. The Resistor is by far one of the most common components used in electronics, yet they are taken for granted. We can often run down to the corner electronics shop and by them, or scrounge them from a thrown out television set. But at one time this wasn't true (and in some countries it still isn't). Until resistors were made comercially available, they had to be fabricated by the person wanting to use or experiment with them. This has become a bit of a lost art, but I'd like to bring it back - simply for the knowledge to be passed down, and for others to perhaps build upon. (Note - if you find any good ideas I do not list, please pass them along to me so I can help share them with the global conscience.

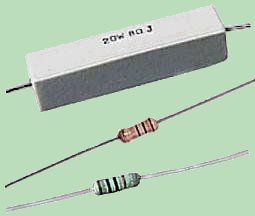

Let us begin with what resistance is. Resistance is the electrical equivalent to friction. It is the opposition to the flow (current) of electrons through a particular material. All materials, regardless of whether they occur in nature, or are man-made, have resistivity. Some materials are more electrically resistive than others. The opposite of resistance, of course is conductance. Some materials are more conductive than resistive. For instance, while rubber is highly resistive, copper is highly conductive. Copper makes a better conductor than a resistor, yet it still has resistance. The amount of resistance a particular material is called "Resistivity" and is represented by the Greek letter ρ. ρ and resistance have a relationship in a material, wherein R=&rho multiplied times the length of the material, divided by the cross sectional area (diameter) of the material. R = ρ * d / ABy this method - if you know the resistivity of a particular material, you can directly calculate the resistance you will have based on how long you cut it and how big around it is. If you want to add resistance, you can make it longer or decrease the area. If you want to decrease resistance, you can make it shorter or increase the area. Etc. Making resistors may seem daunting, until you consider that for years, if you wanted a resistor you had to make them yourself, and during those years - people invented and used things like radios. A pet project of mine I've been looking forward to but not completed is to build a nice radio from all home made components. Alas - perhaps in my retirement. Wire Wound Resistors.All that aside, let us begin with the wirewound resistor. This one is very easy to make. Simply take a piece of very thin INSULATED wire, and wrap it several hundred times around a pen or a pencil. The wire can be insulated by varnish, like speaker wire is, or by just about any other insulative material. The point is that if it is not insulated, and the wrapped coils touch - it simply increases its cross sectional area, and as such - decreases its already low resistance. Keep in mind that it will also act like an inductor in an AC circuit. You can try different metals as well. Use copper wire, bailing wire, try out your guitar strings! That's all there is to it.Carbon Composite Resistors.First - lets begin with one that is already made for you - using your favorite (well, my favorite anyway) writing instrument - the Pencil! Pencils, like carbon compound resistors, are made of a carbon substance (graphite), glued together and wrapped with an insulator (wood). Take a pencil, and cut it carefully with a hacksaw. I say carefully, because you don't want to crack the carbon somewhere in the middle. I use a No. 2 Dixon® pencil. When I cut the pencil, then measure it with an Ohm meter, I find that its resistance is 1Ohm / CM. In other words - if I want an 10 ohm resistor, I simply cut the pencil into an 10 centimeter piece. Now simply devise a way to connect your "leads" to the end of the pencil, and you are done. In my case, I "twist drilled" them into the carbon itself with my fingers. (By the way - the leads I used were the center conductor of the red wire in the above pic....a piece of RG-58 I salvaged from the trash). Then glued them into place with a dollop of hot glue. Of special note is the improvised clamp method I used to hold the resistor while I was gluing it. Any pair of pliers and a rubber band becomes a handy improvised clamp in the field. In the case of the one in the picture, my 10 Ohm resistor came out to about 9.6 Ohms. A 5% tolerance is the Gold Standard of resistors, so I guess I did well. How are you going to do that? The pencil has a fixed diameter of "lead". Yes, but you can write on paper with it can't you? If you simply draw a single "pencil lead thickness" line on a piece of paper, and then put a paperclip on each end of that line, you have a resistor with leads. When I do that with my No. 2 pencil, I get 100KOhms / Centimeter. So a 200K Ohm resistor would be 2 centimeters long. If I want to decrease it to 50K, I can simply draw the line 2 "pencil lead thicknesses". By doing so, you can nearly calculate the length and width of whatever resistor you want to make. Now if you take that particular thickness, and affix leads to it (try tape and copper wire) - you have a resistor. Put it into a hollow plastic tube (think BIC® pen) and seal the ends of it with some kind of epoxy - you have a home made fixed resistor of your favorite resistance value! Experiments:Try using various materials. Glass, Ceramic, Copper, water, silly putty. Test them with an ohm-meter to see what their resistance is. Take notes on what materials are more resistive than others. Devise ways to connect leads to them and make them less apt to break. Think of ways that these could be mass produced in a factory setting. Have FUN!

| |||||||||||||||||||||||||||||||||

[COURSE INDEX] [ELECTRONICS GLOSSARY] [HOME]

| Otherwise - please click to visit an advertiser so they know you saw their ad! |

This Course was written by Ray Dall © All Rights Reserved.

This page and all its content Copyright, Trademarks, Intellectual Properties

and other legal issues 1994, 1995, 1996, 1997, 1998, 1999, 2000, 2001, 2002, 2003, 2004, 2005, 2006 Ray Dall.

All Rights Reserved.

And for what it's worth... this page was last updated HexDate 01-11--7D1